English

English Español

Español  русский

русский  日本語

日本語  Português

Português  Français

Français  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

When replacing the rubber gasket on an old pipe, how can you ensure the new one's dimensions and specifications are fully compatible with the original flange?

2025-10-17

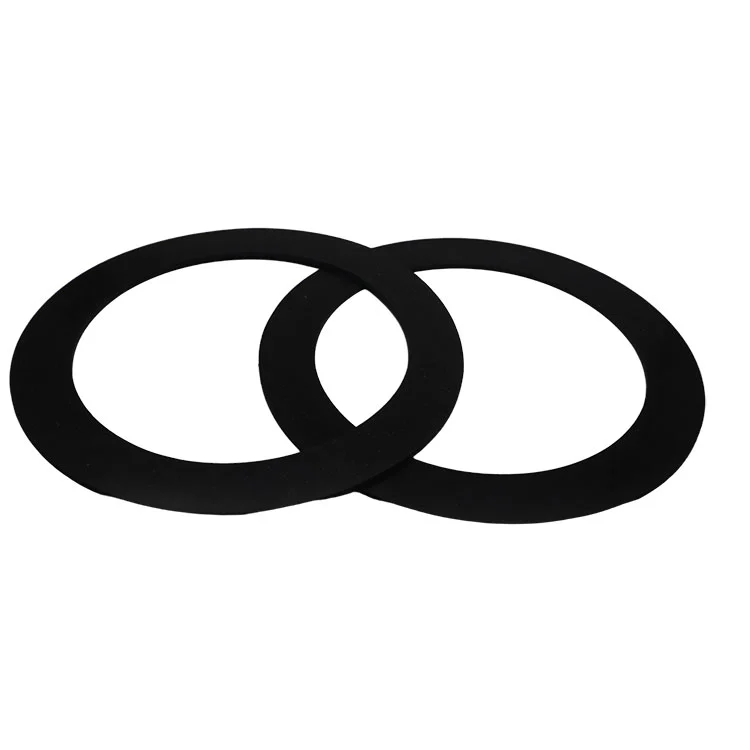

Rubber gasket on pipes is designed to provide a tight seal, preventing leakage of water, oil, and other substances. However, over time, rubber gasket will inevitably develop problems, such as becoming hardened, deformed, or even cracking. This weakens the seal and makes it more susceptible to leakage. Excessive leakage is not only wasteful but can also compromise the safety of the entire piping system, so replacement is crucial.

Measuring Key Dimensions

To determine if a new rubber gasket will fit properly, the first step is to clearly measure the key dimensions of the original flange. Common tools include calipers and tape measures. For extreme precision, vernier calipers or micrometers are more reliable. First, measure the flange's inner diameter, then the outer diameter, and finally the width of the sealing surface.

Original Equipment Documentation

In addition to measuring the flange directly, you can also consult the documentation of the old rubber gasket or equipment to find dimensional information. Some rubber gaskets have markings, perhaps a series of numbers, letters, or special symbols. These indicate the size and model of the gasket. Look carefully and you might find useful information. If there are no markings, consult the equipment manual. This manual will typically detail the specifications of each component, including the dimensions of the rubber gasket. Using this information to select a new gasket is a surefire way to ensure success. Equipment drawings are also very helpful, especially piping system designs, which often include specific dimensions and shapes. These are invaluable references, eliminating the need for laborious measurements.

Compare to Industry Standards and Specifications

Many industries have specialized flange and rubber gasket dimension standards, such as the national standard GB series and the JB series for the machinery industry. These standards clearly define the dimensions of flanges and rubber gaskets for different types and pressure ratings, ensuring you're on the right track. For example, if the standard specifies the required sealing surface width for a flange of a certain pressure rating, then the new rubber gasket should be checked to ensure that the sealing surface width matches. Other dimensions should be checked in the same manner to ensure that the rubber gasket meets the standard requirements.

Post-Installation Testing

Before installing the rubber gasket, carefully inspect its exterior for cracks or deformation. If any problems are found, it should be replaced immediately. Apply a thin, even layer of sealant to the sealing surface of the rubber gasket to ensure a better seal. After installation, a pressure test is essential to check for leaks. First, slowly increase the pressure of the piping system to normal operating pressure and maintain it for a period of time. Carefully inspect the flange joints for any signs of leaks. If a leak is detected, recheck the gasket for proper installation. Once the problem is identified and resolved, retest the system until it is completely leak-proof.

-

E-mail

-

Call Us

-

Address

No.17, Huli Park, Tongan Industrial Concentration Area, Xiamen 361100 China

For inquiries about stabilizer bushing, dust cover, horse rubber parts or price list, please leave your email to us and we will be in touch within 24 hours.